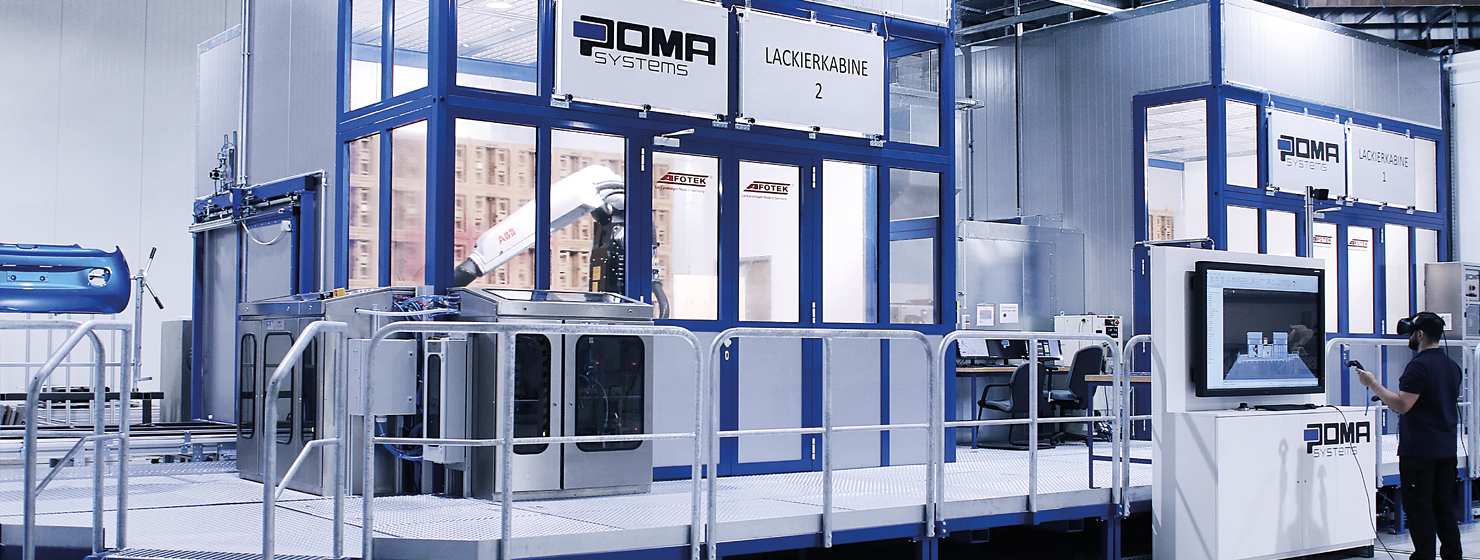

Test Center for solutions around liquid painting. Development and testing of sustainable customer processes.

It took almost one year since the Test Center with a total area of 900 sqm has been completed in 2018. Due to the ingenious conveyor and dryer technologie, 3-coat finishes can be applied in a realistic manner and dried with intermittent aeration.

Individual application methods with 1K or 2K coating are operated with most ecological paint systems. Electrostatic applicators in addition to conventional atomizers are available as well.

This Europe-wide unique Paint Laboratory is the heart for technological innovations of our products and processes. Furthermore, we are now able to support our customers in their production- and material optimization. We are pleased to accompany them on this journey. Christian Mathiak, Managing Director of POMA Systems

The Test Center serves POMA Systems as a breeding ground for innovations in the field of paint technology.

New and existing systems as well as application methods are tested for efficiency and practical suitability. All activities, covering the entire product- and system development process – from the idea to series-production level – are now bundled together. Even the design of piggable paint supplies can be checked for loading, unloading and rinsing times under real conditions.

Customer-specific tests for leading results.

Customers have the opportunity to experience POMA processes and technologies live. Tests and developments on behalf of the customers are possible as well. With this Test Center, all important process parameters can be defined before delivery or even in the quotation phase. Due to the wide range of testing methods, it is possible to develop customer-specific solutions that are ideally and precisely tuned to ensure successful production results.

Programming painting robots using virtual reality

The painter holds a kind of transmitter in his hand, whose movements in the room are recorded by two detectors and transmitted in real time to a powerful PC. A special software on the PC now combines all information into a virtual image, which enables the painter to "paint" the workpiece. The movement paths of the spray gun relative to the workpiece are saved in the PC. This information can be transferred to the kinematics of the painting robot used. The painting program generated in this way can then be corrected or optimized as required on the PC. After that, nothing stands in the way of using the line.

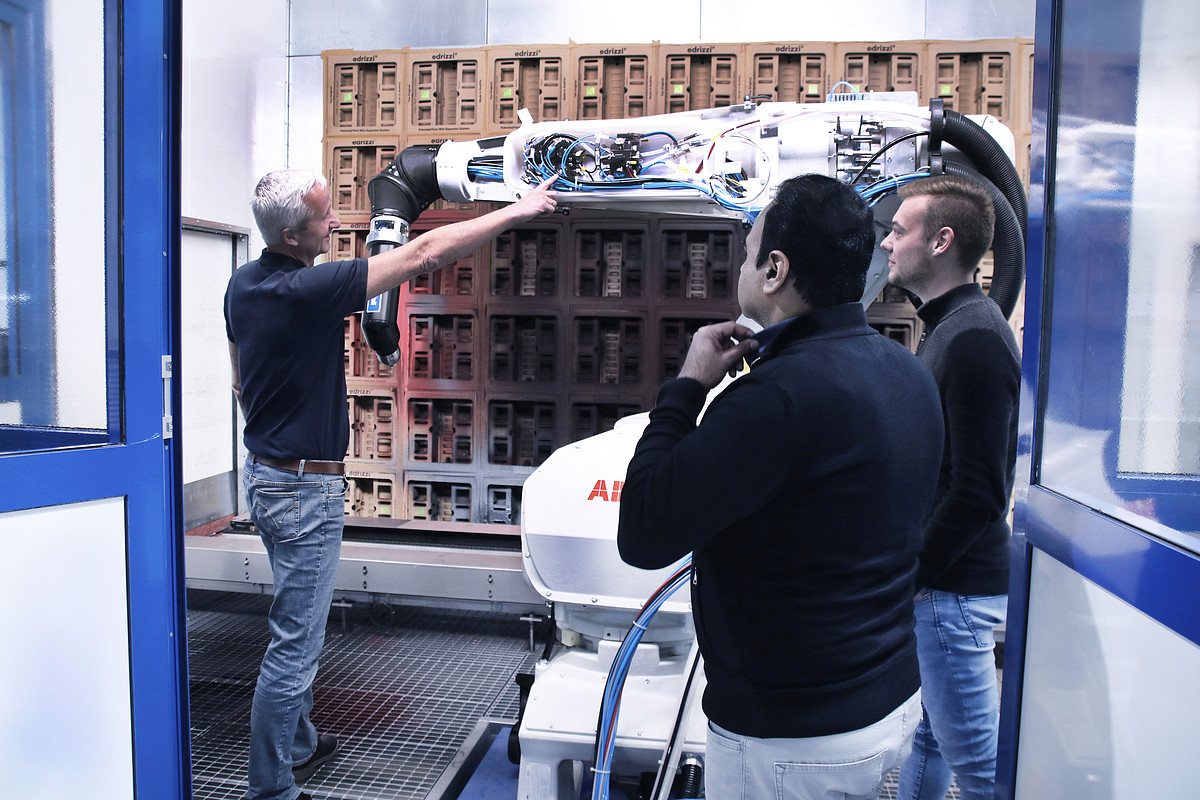

Individual workshops.

The training of our customers is essential for the optimal use of our processes and technologies. Only those who know the products and systems can fully use the quality and performance potential of our products. For this reason, we offer needs-oriented and individual training courses in our technical center, in which all questions can be practically simulated and applied together with our experts.

Technical features

- Two booths with paint robots

- Conveyor technology

- Dry aspiration

- Paint dryer: 50 – 150 °C ± 5°C

- Supply-air humidification: 65 ±10 % relative humidity

- With and without electrostatic technology

- 2K-Dosing system

- Pigging technology

- Electrical isolation

- i-XS atomizer exchange system

- Robot simulation