A hand on the tiller

Human expert retains control

It is impossible to imagine modern factories without partially automated workstations. Automation does not make sense in every situation. Examples of situations where partially automated manual workstations are more suitable include dealing with small batch sizes, great diversity of product type and large numbers of variants. In terms of quality assurance, reliable final and interim controls are not possible here without human intervention, with a human’s greater sensory capabilities and expert knowledge. A sensible mix of automation and human work increases productivity and safeguards the site’s future. The idea that manual work is in principle superior is a myth. The speed, accuracy of reproduction and precision of modern production standards are achievable only through automation.

Quality assurance

Product quality and avoiding complaints

Partially automated manual workstations are thus in no way an expression of simple, primitive work. It is precisely in the case of complex assembly processes, i.e. where people cannot be replaced or where this can be done only with significant engineering expenditure, that partially automated manual workstations are an indispensable component of any production operation aiming for high standards of quality. One side-effect of all automation projects that is rarely fully appreciated is a gradual increase in the level of workers’ skills. Leading edge technology, high-tech equipment, manual work and the experience of a highly qualified workforce complement each other ideally.

Example 1

Fuel pump production

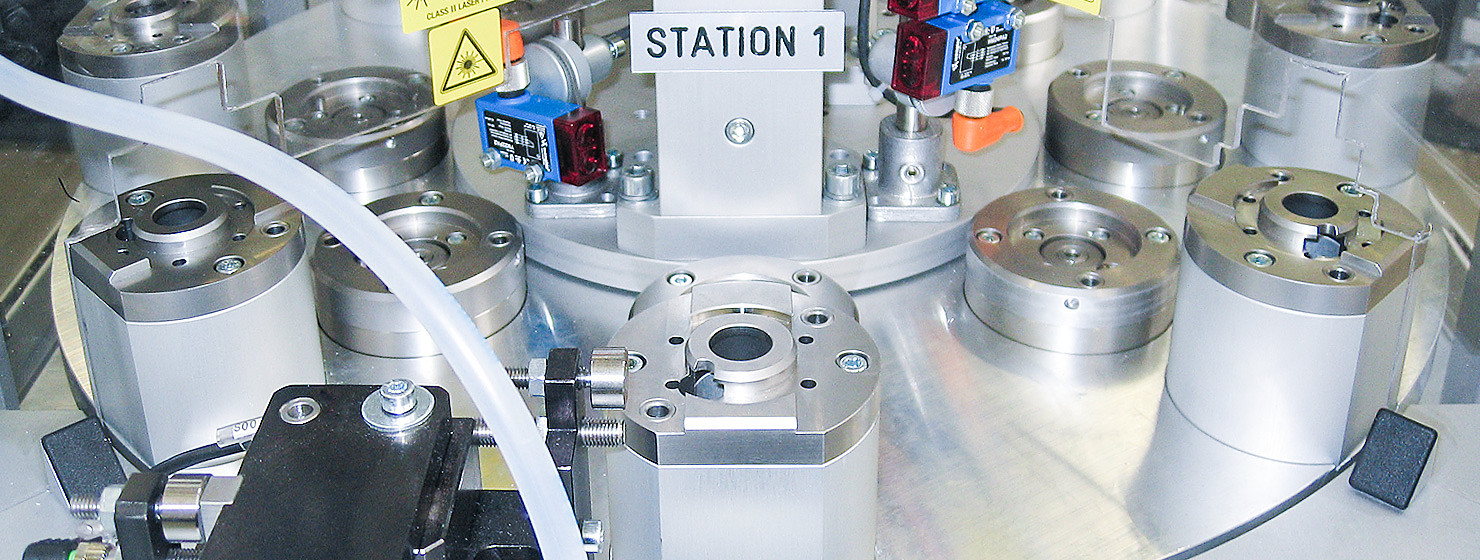

- Rotary indexing table for making fuel tank pumps

- Makes a valve with ball and spring

- Force fits a clamp

- Checks the tension

- Checks for leaks

- Compresses lid with stator and rotor

- Client: Continental Automotive GmbH

Example 2

Vehicle display test stand

- Stand for feeding units with power

- Tests 30 displays or combined units

- Tests the systems in powered up state

- Client: Continental Automotive GmbH