From precision parts to assembly systems

POMA Systems has highly specialised manufacturing resources for the construction of bespoke equipment and the contract production of mechanical components.

The manufacturing technology is divided into three areas:

- Complete System Factory Automation

- Assembly plants , manufacturing equipment , robotics

- Systems for paint automation

- Prototype

- Test facilities

- Modifications

- Individual and small series

- Assemblies and components

- Custom

- Parts

All-around client support from A to Z

Requirements for the highest standards of manufacturing quality lead inevitably to a desire for even greater independence. As we all know, too many cooks spoil the broth. The more interfaces there are in a chain of suppliers and sub-suppliers, the more the product quality is put at risk. The more adherence to deadlines, success of the project and the relationship with the client is put at risk. As a matter of principle, we therefore refrain as far as possible from working with sub-contractors.

All-around client support from A to Z: That means process control and quality assurance through levels of vertical integration of up to 80% and more. At POMA Systems, for instance, we have our own joinery so that we can, for example, produce high quality packaging systems with great precision and to our own designs. So that delicate products do not get delivered in pieces. We leave nothing to chance. The company thus operates as a self-contained, synergistic loop.

1. Complete system production

Assembly systems, production systems and robotics

As a cross-disciplinary function manufacturing technology is allocated to the company’s custom engineering and automation divisions, just as it is to our test systems, process control and painting automation operations. The same production resources are used as feature in prototype construction and the manufacture of individual parts. The transitions between the individual areas are fluid. Prototype construction, for instance, is very often linked with the individual production of components that are not available on the market. A production system is generally prototype-like in character.

Further information:

- Custom engineering and automation

- Test systems and process control

- Painting automation

2. Prototypes

Manufacturing equipment for prototypes

Our involvement in prototype construction originally stemmed from our own requirements. Building prototypes means entering new territory, constructing something for the first time or making new modifications. It can be individual assemblies with self-contained functions or, at a higher level, complete systems for client-specific applications. These are one-offs and trial systems, which, where applicable, we then manufacture in short production runs.

Joint venture projects

In the engineering of prototypes we act both as an ideas factory and a sparring partner. Our prototype construction services are aimed at clients who generally possess their own development know-how but do not have the necessary resources for engineering and realisation. The products concerned are frequently at the leading edge of custom machine building technology.

For example

- Electron beam gun for high-vacuum welding in gearbox production

- Shoe production: Manufacturing system for the compression moulding of soles with difficult mix of materials

- POMA Systems automatic spray gun

POMA developments

Prototype construction for painting equipment

As a manufacturer of painting systems and hardware components for painting applications and equipment, new developments and product enhancements are part of our daily routine.

For example

- Material pressure regulators

- Gear dosing pump designs

- Gun adapters

- Hinged 2-component mixers

- Hose adapters for industrial robots

3. Short runs and individual parts

Manufacturing equipment for parts production

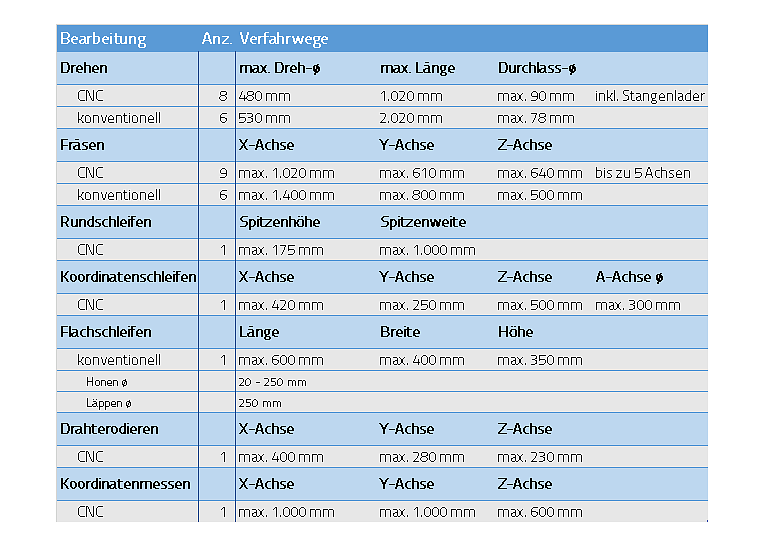

This is the level of contract production of individual mechanical parts, assemblies and custom-built equipment. The requirements vary between one-off production, short runs and medium-volume runs. The materials used include, for example, chemically resistant grades of stainless steel (material numbers 1.4571, 1.4301 or 1.4112) as well as aluminium and plastics. POMA Systems does no mass production. All of the company’s machinery is geared to the manufacture of precision mechanical products of the highest engineering standards. In terms of manufacturing technology, POMA Systems acts as many clients’ extended workbench.

For example:

- Milled parts and brackets

- Nozzles and valves

- Adapters and threaded joints

One-off production, short runs and custom builds

Contract production of precision components is aimed in particular at clients with a special need for highly precise mechanics. We deal here with components that are either not available at all on the market or not at the desired level of quality. Special equipment for painting automation, in particular, also falls into this area.

4. POMA Systems - Machinery