Free of ties

Stand-alone island systems or part of an assembly line

An assembly cell is either designed as an independent stand-alone system or as part of an assembly line. Assembly cells are often rotary systems with high speeds and short cycle times that are used to fit a relatively small number of elements to small components such as shaver heads, control units or displays.

Functional aspects and space requirements

Compared to linear systems, isolated stations and rotary systems have the advantage of being more accessible. Systems linked in a line, on the other hand, allow any number of complex tasks. Everything larger than module size is generally manufactured using linear technology.

Example 1

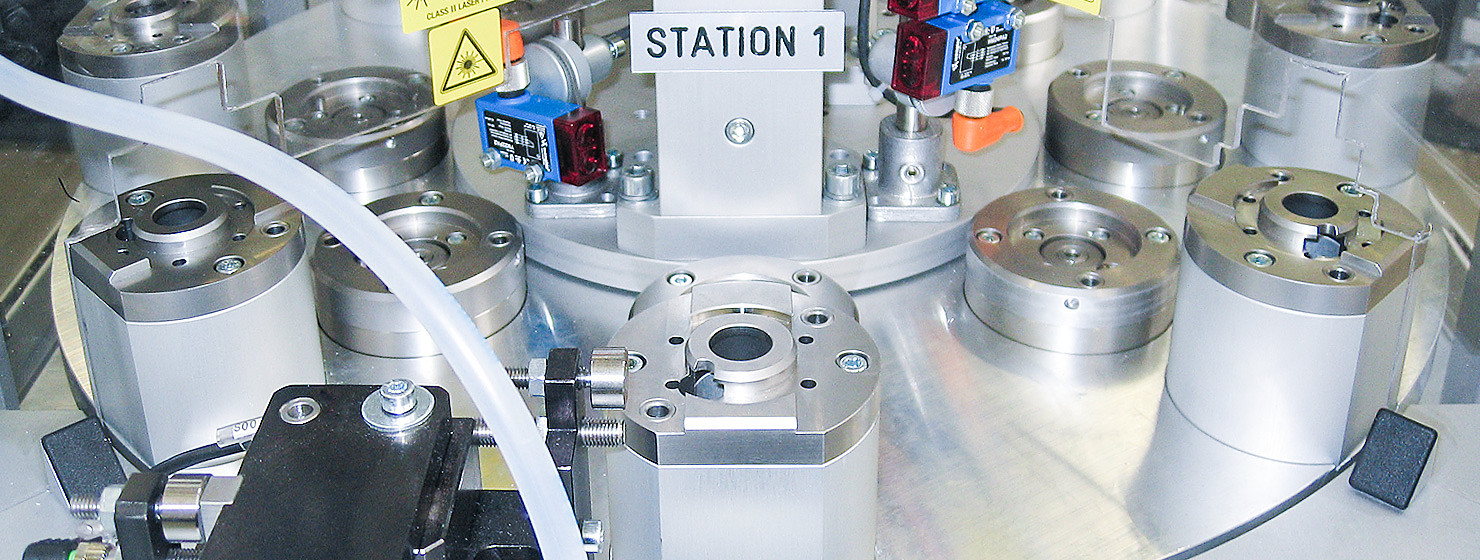

A torque motor assembly cell

- Rotary indexing table (8 stations)

- For assembling L-stators, I-stators and solenoids

- Isolation testing

- Inscribing

- Sifting out defect parts

- Client: Continental Automotive GmbH

Example 2

Inline roller tappet assembly cell

- Linear transfer system

- Skims roller tappets

- Presses on a link

- Monitors force / path

- Inserts a screw

- Easy to service and space saving: the protective housing can be moved up out of the way

- Client: Schaeffler Technologies