Logic meets practice

Common automation concept

In the project, the automation concept is developed jointly between POMA Systems and the client. This is where it is decided whether robotics or linear axes are used. An essential criterion is the reliability of an assembly system. As a matter of principle, POMA Systems manufactures all mechanical parts and assemblies itself that are not available on the market. Supplier products are modified on a case-by-case basis as long as they meet our requirements for manufacturing precision, functionality and practicality.

Modular design in linear arrangement

Short innovation cycles require flexible production conditions. The result is a desire for systems that can be used variably and short set-up times. Theoretically, ideally, only the same system would be used just in sequence with different software. A conceivable ideal case, which in practice hardly corresponds to the reality of automation. We take account of the need to adapt quickly to changing market conditions with modular plant concepts.

Example 1

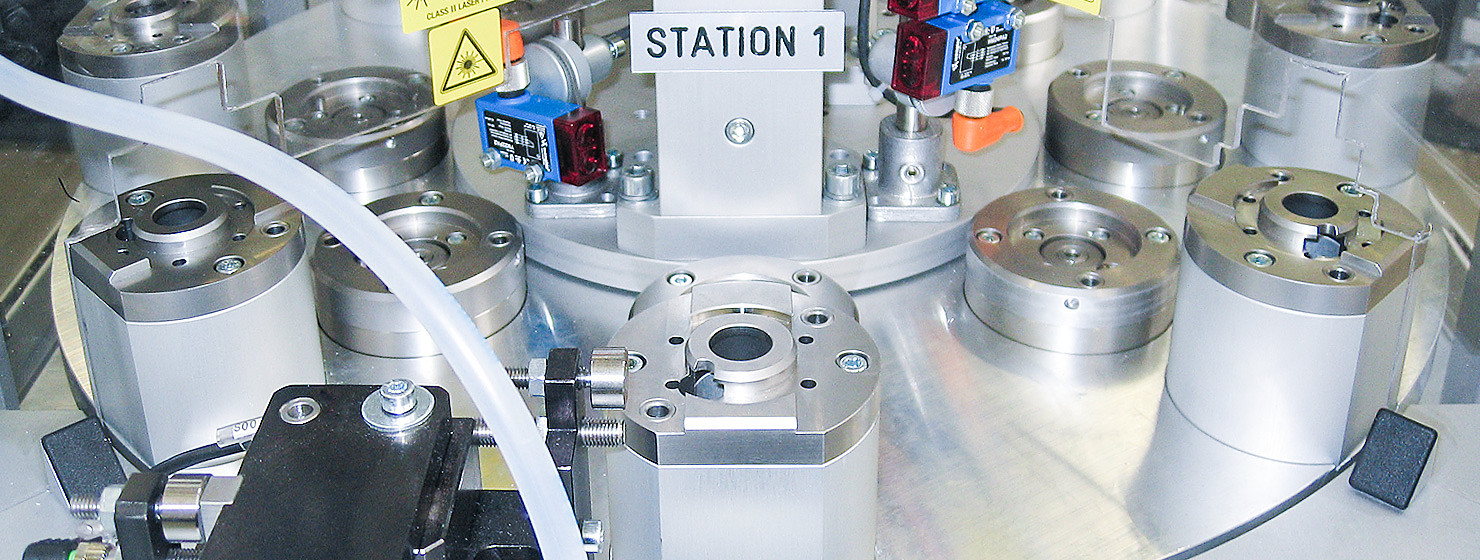

Assembly line - workpiece pairing and assembly

- Bosch transfer technology

- 13 fully automated individual stations

- Camera check

- Dosing

- Pair, press and assemble workpieces

- Customer: Schaeffler Technologies

Example 2

Assembly line inline - wheel bolt assembly

- Installation of wheel bolts on disc brakes and brake drums

- Linking via POMA transfer technology

- Robot-assisted wheel bolt assembly using two hydraulic press-in tools

- Chaotic feeding of the workpieces

- Detection via sensors

- Customer: SAF Holland